Qt4-25 Automatic Hollow Solid Concrete Cement Paving Interlock Wall Building EPS Wall Brick Block Production Line Block Making Molding Machine Supplier

QT4-25 Automatic Block Making Machine QT4-25 cement brick making machine is a kind of automatic product developed by our

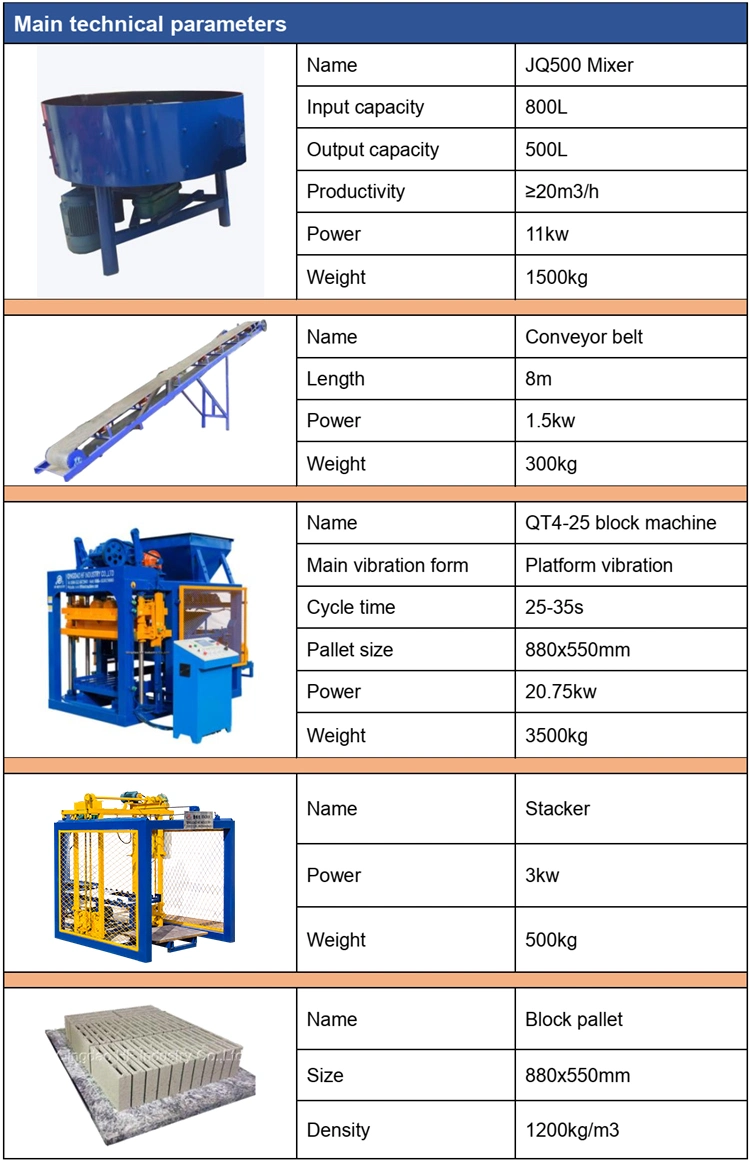

Basic Info

| Model NO. | QT4-25 |

| After-sales Service | Local Service |

| Certification | CE, ISO, SGS |

| Customized | Customized |

| Automatic Grade | Automatic |

| Type | Vibration and Hydraulic |

| Voltage | 220V/240V/380V/415V/440V |

| Power | 20.75kw |

| Pallet Size | 880X550/910X550mm |

| Weight | 3500kg |

| Productivity | 400*200*200mm Blocks 3200-4560 Pieces/8hour |

| Hydraulic Pressure | 16MPa |

| Model No | Qt4-25 |

| Color | Optional |

| Factory Area | 1500m² |

| Transport Package | Container |

| Specification | 6400x1500x2700mm |

| Trademark | HF |

| Origin | China |

| HS Code | 8474802000 |

| Production Capacity | 8000PCS/H for 400X200X200mm Block |

Product Description

QT4-25 Automatic Block Making Machine

QT4-25 cement brick making machine is a kind of automatic product developed by our company newly, adopts flatvibration, mold vibration, and squeeze compression vibration, manufactures the blocks with average density and highstrength. And the unique dose charging device and the strong material-distributing structure ensure the block'squality of various materials. It adopts PLC control, and realizes the automatic plate-supplying, material-distributing,and brick-discharging. With the high efficiency, it is the ideal equipment to manufacture the new style wall material.

| Technical specifications | |

| Model | QT4-25 |

| Overall Dimension | 6400*1500*2700mm |

| Cycle Time | 26s |

| Total Power | 20.75KW |

| Pallet Size | 880*550/910*550mm |

| Raw Materials | crushed stone, sand, cement, dust and coal fly ash, cinder, slag, ganaue, gravel, perlite, and other industrial wastes. |

| Applied Products | concrete blocks, solid/hollow/cellular masonry products,paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| Applied Fields | widely used in buildings, road pavings, squares, gardens. landscaping, city constructions, etc. |

Our service

1) Send the technicians to carry out the installation and debugging of equipment for the foreign users with compensation.Countries or regions with unstable political situation or in the throes of wartime are not included in our plan.

2) Train the users to command the equipment and guide them for safe production.

3) Explain the routine maintenance of equipment carefully and remove common faults.

4) We are responsible for all the repairs that caused by our quality problems within one year's warranty. (We will provide one set of spare parts/wear & tear parts free of charge with shipment.)

5) For some countries whose visas are difficult obtained, customers can also send their technicians to our company to receive free guidance and training.

6) Accept suggestions for improvement put forward by customers an earnest way. In accordance with changes of the market, provide the products and services to meet the user's needs and create value for them.

7) We will make every effort to solve your problems, and your success will add new CONFIDENCE.

If you interested in our block machine, please feel free to contact me.

Send to us