Stainless Steel Steam Double Jacket Blender Solution Preparation Mixing Tank

Package size per unit product 300.00cm * 300.00cm * 800.00cm Gross weight per unit product 800.000kg The Marked Prices O

Basic Info

| Model NO. | RT-19 |

| After-sales Service | Online Support, Video Technical Support |

| Warranty | 1 Year |

| Type | Tank Reactor |

| Material | Stainless Steel |

| Capacity | 500L-10000L |

| Structure | Filling Tube |

| Pressure | Positive |

| Agitator Model | Turbine Agitator |

| Tower Reactor Type | Spray Tower Reactor |

| Heating | Outside (Inside) Coil Heating |

| Heat Transfer Structure | Jacketed |

| Automatic Grade | Automatic |

| Condition | New |

| Function | Heating or Cooling |

| Sealing Type | Mechanical Seal, Packing Seal |

| Agitator | Anchor, Paddle, Frame |

| Voltage | Customer Required |

| Transport Package | Wooden Case with Steel Frame |

| Specification | stainless steel |

| Trademark | JNBAN |

| Origin | Wenzhou, China |

| Production Capacity | 1000pieces/Year |

Packaging & Delivery

Package size per unit product 300.00cm * 300.00cm * 800.00cm Gross weight per unit product 800.000kgProduct Description

The Marked Prices Of Our Products Are All Range Prices Of The Entire Product Series.If You Need a Detailed Quotation, Please Send An Inquiry At The Bottom Of The Page.

Customized part1. Volume: 100 ~ 10000L

2. Material: SS304 , SS316 ; Carbon steel , Lined PTFE

3. Agitator: anchor , frame , paddle , multifunction type (frame, dispersing mixer, emulsify mixer) etc.

4. Type: single layer, double layer (with jacket to heating or cooling), external coil-pipe type

5. Heating method: electric heating, steam heating, circulation oil heating, infrared heating etc.

6. Warranty: 1 year

7. We support customization.

| Model | 100L | 300L | 500L | 1000L | 2000L | 3000L | 5000L |

| Mixing Motor Power | 1.1KW | 2.2KW | 2.2KW | 4KW | 5.5KW | 7.5KW | 15KW |

| Heating Motor Power | 12KW | 24KW | 36KW | 48KW | 60KW | 75KW | 90KW |

| Inner Layer Size (Dmm) | 500 | 800 | 900 | 1200 | 1400 | 1600 | 1800 |

| Jacket Size (Dmm) | 700 | 1000 | 1100 | 1400 | 1600 | 1800 | 2000 |

| Inner Plate Thickness | 5mm | 5mm | 5mm | 6mm | 6mm | 8mm | 8mm |

| Jacket Plate Thickness | 5mm | 5mm | 5mm | 6mm | 6mm | 8mm | 8mm |

| Material | SS304, SS316L, Carbon Steel; It also can lined PTFE. It can be customized to meet your requirement. | ||||||

| Heating Type | electric heating, steam heating, oil circulation heating etc. | ||||||

| Agitator | anchor, paddle, frame etc. | ||||||

| Sealing Method | packing seal or mechanical seal (vacuum) | ||||||

| Model | We still have more models. (6000l, 8000l, 10000l, 15000l, 20000l, 30000l etc.) | ||||||

FAQ

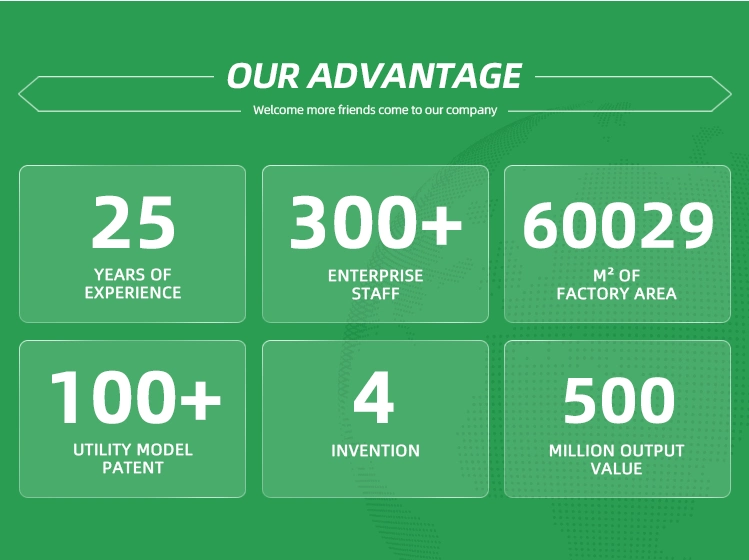

Q: Where is Your Factory? How Can I Visit Your Factory?

A:Our Factory is Located on WenZhou Zhejiang Province. We Are Warmly Welcome You to Visit Our Factory if You Have a Travel Plan

A: If you don't mind, you can send a sample and we test it on the machine. During that time, we will take video and clear picture for you. If chance, we can take video online and show you.

Q: Is there any installation direction after we received the machine?

A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.

The machine will have one year warranty. During the warranty year if any of the parts broken not by man-made. We will free charge to replace the new one to you . The warranty will begin after the machine send out and we received the B/L

Send to us