Chinese Manufacturer EPS Plastic Foam Hot Melt Machine Machinery for Recycle

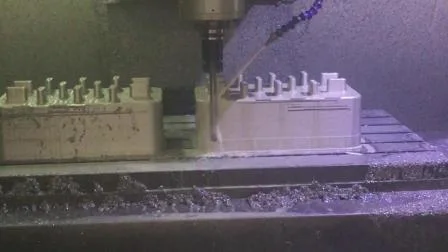

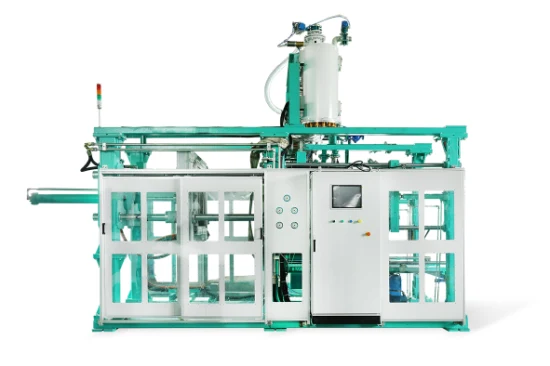

Overview Chinese Manufacturer EPS Plastic Foam Hot Melt Machine Machinery for Recycle The plastic granulating unit is a

Basic Info

| After-sales Service | Online Support |

| Warranty | 1 Year |

| Raw Material | PE |

| Screw | Single-Screw |

| Inverter | Inverter |

| Electromagnetic Heater | Electromagnetic Heater |

| Automation | Automatic |

| Computerized | Non-Computerized |

| Customized | Customized |

| Certification | CE |

| Condition | New |

| Capacity | 500kg/Hr |

| Power | 180kw |

| Color | Customize as Client′s Request |

| Transport Package | Wooden Case |

| Trademark | Shuliy |

| Origin | China |

| Production Capacity | 15sets/Month |

Product Description

Chinese Manufacturer EPS Plastic Foam Hot Melt Machine Machinery for Recycle

Parameter of plastic film recycling line

| NO. | Item | Technical data |

| 1 | Conveyor | Power:3kw Size: Length 5m , Width 0.8m Capacity:1000-1200kg/h |

| 2 | PP PE crusher | Model:1000 Power :37kw+11kw Capacity :1000kg/h |

| 3 | Belt Conveyor | Power :1.5kw Size : (L) 4m* (W) 0.6mm Capacity:800-1200kg/h |

| 4 | Automatic Feeder | Power:3kw Capacity:800-1200kg/h |

| 5 | Main Plastic Pelleting Machine | Model : SL-260 Screw diameter : 260mm Screw length:3.6m Motor : 110kw |

| 6 | Vice Plastic Pelleting Machine | Model : SL-220 Screw diameter : 220mm Screw length:L1.6m Motor :22+18.5kw |

| 7 | Pellet Cutting Machine | Model :LY-F300 Power :7.5kw Capacity: 800kg/h |

| 8 | Plastic Pellet Baging Machine | Power :1.5kw Size :1000*1200*1100mm |

Company ProfileOur Advantages

CertificationsFAQ

Q1: Are you a manufacturer or trade company?

A1:We are a professional manufacturer for producing machinery over 10 years.

Q2: How is the quality of your product?

A2: Our products are manufactured according to national and international standard, and we have a test on every machine before delivery.

Q3: How about the price?

A3: We are a professional manufacturer and be able to provide you with the lowest price than market one. We will give you the best quotation.

Q4:What if the machine is damaged?

A5: One year warranty and all-round after-sales service. After this deadline, we shall charge at a low cost to keep after-sales service.

Send to us