16bar Electric Industrial Screw Air Compressors for Fiber Laser Cutting

Basic Info

| Model NO. | DBZY-20A |

| Structure Type | Closed Type |

| Installation Type | Stationary Type |

| Type | Single Screw Compressor |

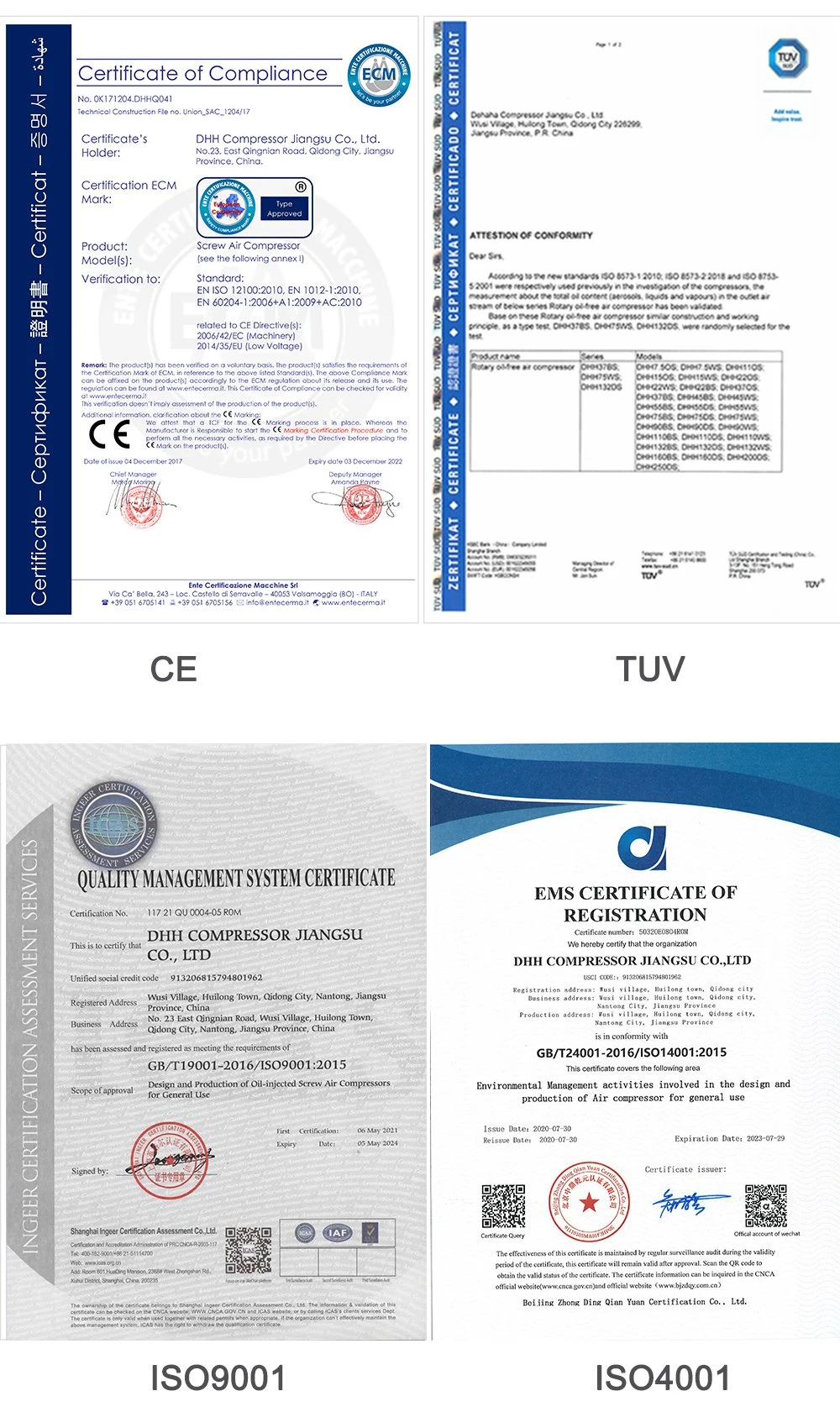

| Certificate | CE/ISO9001/TUV/SGS |

| Cpacity | 1.51m3/Min 53.3cfm |

| Pressure | 7~13bar |

| Air End | Rotorcomp/Ghh/Hanbell |

| Motor | Siemens/ABB/Weg |

| Motor Protection Level | IP54/IP55/IP65 |

| Inverter | Siemens/ABB/Inovance |

| Weight | 572kg |

| Air Tank | 500L |

| OEM | Welcome |

| MOQ | 1 Set |

| Start Method | Frequency Conversion Start |

| Application Industry | Fiber Laser Cutting Application |

| Transport Package | Plywood Case |

| Specification | 1882*790*1731mm |

| Trademark | DHH |

| Origin | Shanghai, China |

| HS Code | 8414809090 |

| Production Capacity | 600units/Month |

Product Description

| Suitable for laser cutting machines below 6000W | |

| Air cutting requirements | working pressure:16barflow:1.5m³/minair storage tank:500L |

| Filtration accuracy | using four-stage filtration, particle ≤0.01μm oil treatment ≤0.003PPM |

| Equipment configuration | screw air compressor, air storage tank, cold dryer, four-stage filtration system, automatic drain valve" |

| Cold dryer | 16bar/2.4m3/2-10ºC |

| Filter | 16bar/2.8m3/4 pieces |

| Motor protection class | IP54 |

All in one solution SCREW AIR COMPRESSOR SCREW AIR COMPRESSOR SCREW AIR COMPRESSOR

DEHAHA ALL IN ONE series compressed air system integrates screw air compressor, refrigerated air dryer, and air receiver tank into one assembly. This compact assembly provides a complete solution to produce clean and dry screw compressed air. Simplicity in just connecting an outlet pipe, drain pipe, and electrical cables to the system saves cost and space.Product features

1. One-piece integration, small space occupation, easy to install and move.2. Permanent magnet frequency conversion, high efficiency and energy saving.3. Provide compressed air that is pure and dry to almost anhydrous and oil-free.4. Multiple protection devices, multiple shock and noise reduction configurations, low noise

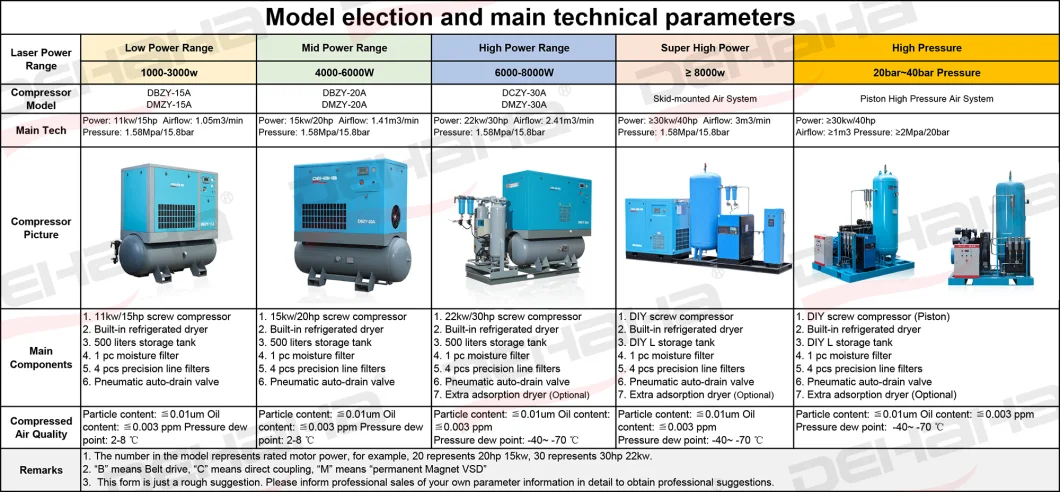

Technical Parameters

| Model | Air Delivery (m3/min) | Rated exhaust pressure (Mpa) | Power (kW) | Noise (Db) | Outlet diameter (In) | Dimension (mm) | Weight (Kg) | Exhaust pressuredew point (ºC) | Exhaust dustcontent (μm) | Exhaust oil content (ppm) | Gas storage tank capacity (L) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DBZY-10A | 0.55 | 1.58 | 7.5 | 65 | G3/4 | 1418*700*1500 | 395 | 2~10 | 0.01 | 0.01 | 260 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DBZY-15A | 1.05 | 1.58 | 11 | 65 | G3/4 | 1882*790*1731 | 560 | 2~10 | 0.01 | 0.01 | 500 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DBZY-20A | 1.51 | 1.58 | 15 | 65 | G3/4 | 1882*790*1731 | 572 | 2~10 | 0.01 | 0.01 | 500 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DMZY-15A | 1.05 | 1.58 | 11 | 65 | G3/4 | 1882*790*1731 | 560 | 2~10 | 0.01 | 0.01 | 500 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DMZY-20A | 1.52 | 1.58 | 15 | 65 | G3/4 | 1882*790*1731 | 572 | 2~10 | 0.01 | 0.01 | 500 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DMZY-30A | 2.41 | 1.58 | 22 | 68 | G3/4 | 1882*1081*1801 | 630 | 2~10 | 0.01 | 0.01 | 500 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DCZY-30A | 2.21 | 1.58 | 22 | 68 | G3/4 | 1882*1081*1801 | 630 | 2~10 | 0.01 | 0.01 | 500 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

Customer feedback

Company ProfileDehaha Compressor was founded in 1996 with over 150 skilled employees and more than 25 R&D engineersteams ' .We focus on the research & develop,manufacture and energy-saving solutions of screw air compressor to create value for customers and society.In 2018 our total sales volume approached 15 million US dollars.By over 23 years enhanced experiences of designing,producing and marketing,today our valued customers are over 130 countries.Germany Standard and 13 years exporting experience help us won more than 50 loyal overseas agents.

Dehaha's primary businesses focus in following key areas:

Oil-injected rotary screw compressors

Portable screw air compressors

Oil free air compressors

High pressure air compressors

Air treatment equipment

At Dehaha,we earn our customers' trust and satisfaction by manufacturing the superior quality compressed air

products for all industries.All of our products are designed for reliable performance,easy maintenance,and maximum energy efficiency.We have sales representatives who can speak English,Spanish,French,and Russian which makes it easier for our clients from all over the world to interact and negotiate with us.

Dehaha continuously innovates product development and management to meet customers' demand.The powerful enterprise culture and continuous innovation make Dehaha improved rapidly to reach the business principle"Energy Saving First, Mutual Value Shared". Dehaha mission is to be a world-renowned high-end brand,with sustainable development,constantly improving its own value and sharing it with our customers and staff.Committed to offer our customers a silent and energy-saving manufactured products.

Our service1.24/7 after sales service support in different languages.

2.Follow up the feedback of products in 2 months interval by email or call.

3.Guidance of installation and commissioning on site can be provided by factory-trained technicians or local Authorized Service Center.

4.Technical training for customers in DEHAHA air compressor factory or working site.

5.Plenty of original spare parts with proven quality are all available from our central stocks in Shanghai and all distributors'depots.

6.All kinds of technical documents in different languages.

Q1. Are you trading company or manufacture ?

A: We are professional manufacture of screw air compressor of Jiangsu, China, more than 24 years.

Q2. How long is the delivery time ?

A: For standard voltage ,15 working days. Non-standard ,please contact our sales.

Q3. What's payment term ?

A: T/T, L/C, D/P, Western Union, Paypal, Credit Card, and etc. Also we could accept USD, RMB, Euro and other currency.

Q4. How about your after-sales service ?

A: 1.Provide customers with installation and commissioning online instructions. 2. Well-trained engineers available to overseas service. 3.Worldwide agents and after service avaiable.arrange our engineers to help you training and installation.

Q5. How about your warranty?

A: One year for the whole machine and two years for screw air end, except consumable spare parts.

Q6. Do you have any certificate ?

A: Yes, per different customer's market need ,we can offer CE ,ISO etc certificate.

Q7. What about the maintenance ?

A: First maintenance need to be done after 500Hours, and then every 2000-3000 hours to do the normal maintenance, and consider the actual environment.

Q8. How do you control quality ?

A: 1.The raw materials are strictly inspected 2. Some key parts are imported from overseas 3.Each compressor must pass at least 5 hours of continuous testing before leaving the factory.

Q9. Do you offer OEM service ?

A: Yes.Both OEM & ODM service can be accepted.

Q10.How long could your air compressor be used?

A: Generally, more than 10 years.