1000L Gallon Stainless Steel Vacuum Steam Electric Heating and Cooling Double Jacketed Reactor Storage Mixing Tank

Basic Info

| Model NO. | 50L 100L 300L 500L 1000L 2000L 3000L 5000L 10000L |

| Operating type | Continuous Operating |

| Condition | New |

| Brand Name | Kexinda |

| Power | Customized |

| Key Selling Points | Competitive Price |

| Contact Material | SUS304/316 and Carton Steel |

| Color | Customized |

| Transport Package | Three-Layer Plywood |

| Specification | 50L 100L 500L 1000L 5000L 10000L. etc |

| Trademark | KEDA |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 10set/Month |

Product Description

We will offer you price referring to your detail request, so please kindly inform us of the material, viscosity, density, etc, andother requirements you prefer, and the special offer will be given.

The pictures are above just for your reference.

Our machines can be customized, leave an inquiry to know more details about price, packing, shipping and price.Any questions, feel free to contact us.

Lusa Ti

| 1000L Gallon Stainless Steel Vacuum Steam Electric Heating and Cooling Double Jacketed Reactor Storage Mixing Tank |

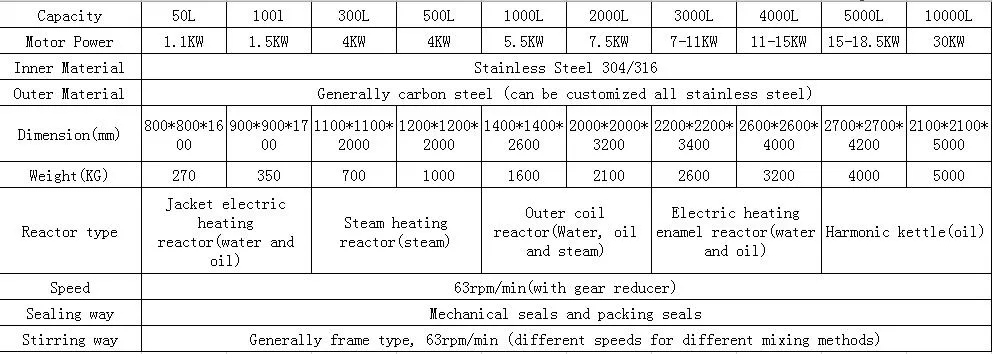

Stainless steel reactor is a new type of reaction equipment developed on the basis of absorbing domestic and foreign advanced technology. It has the characteristics of rapid heating, hightemperature resistance, corrosion resistance, hygienic, no environmental pollution, no need for automatic heating of boiler, easy to use and so on. Used in petroleum, chemical, rubber, pesticide, dyes, medicine, food, used to complete the curing, nitrification, hydrogenation, alkylation, polymerization, condensation and other process

Reactor structure diagram

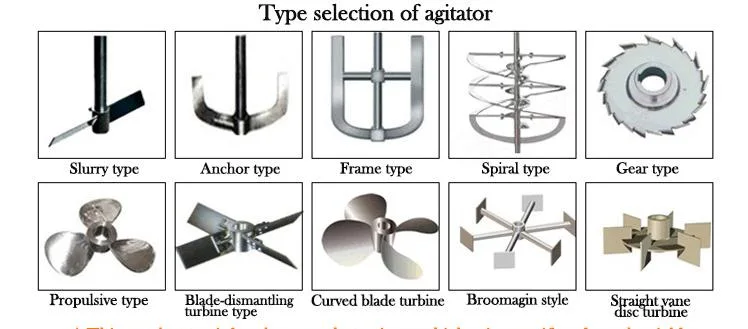

Different mixing methods, different mixing speeds. Usually in the form of a frame stirrer, 63/85 RPM/min. Speed converter can be added to achieve speed control.

The equipment consists of a vertical condenser, a horizontal condenser, a reaction kettle, a water storage device and a fractionation column. It is a special equipment for producing unsaturated polyester resin. Unsaturated polyester resin equipment has reasonable design and advanced technology. It is the most ideal unsaturated resin production line in the domestic market. Users can order from our company according to their annual production capacity and technical requirements.

FAQ

Q: Do you have machines in stock?

A: Yes, but just the small-scale machines. Machines are different with other products, most of the large-scale machines are designed according to our customers' requirements, different customers have different production requirements, so the technical parameter is different for most machines. On the other hands, most of the our machines will cover a large area, so once the machines are finished, we will effect shipment after QC.

Q: Can you send the detailed drawings of the machine to us before we place order?

A: We can send you a draft drawing of the machines, and after you place order and pay the deposit, our engineer will design the specific technical parameters for you and send you the detailed drawings. Once you confirm without questions, we will put it into production.

Q: Can we pay the balance after we receive the machines and test without problems?

A: It's unnessary to worry about the quality of our machines, we are confident in that. After the machine is finished, we can install and test the machine for you (if you can not come to our factory, we can record a vedio and send to you). Only after you check without problems, we will effect shipment.

Contact to me